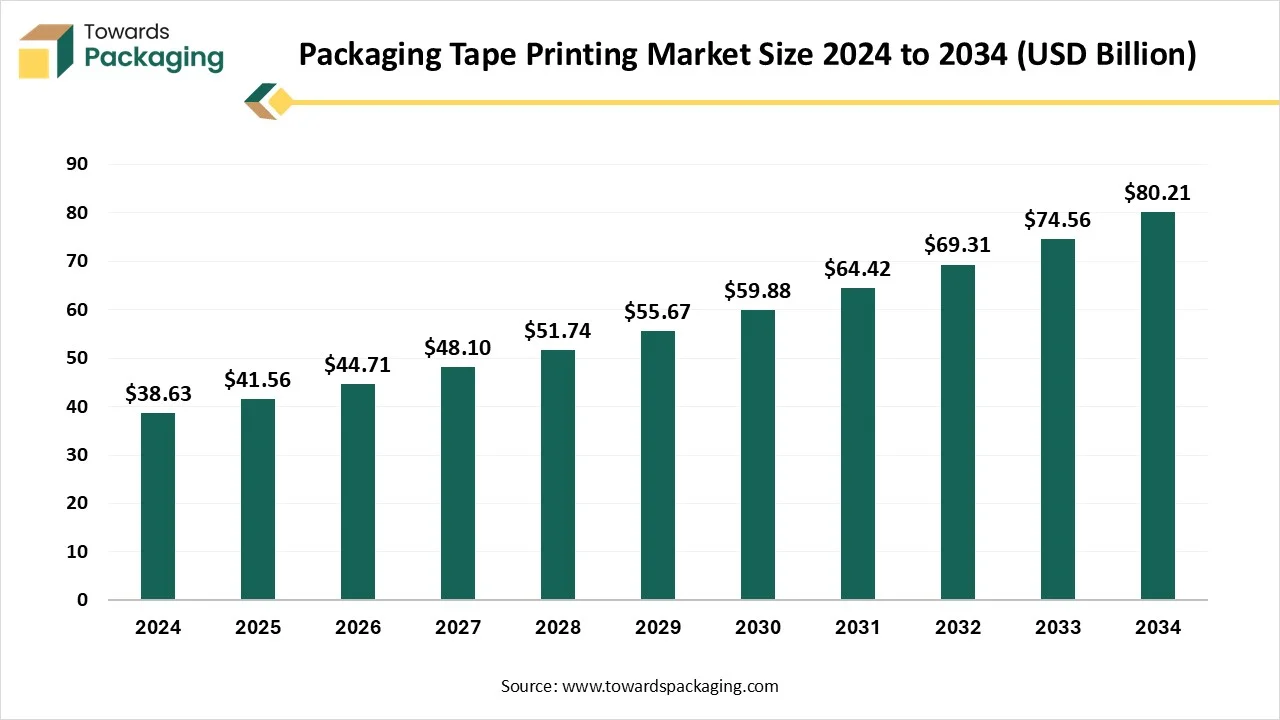

Packaging Tape Printing Market Worth USD 80.21 Bn by 2034 says Towards Packaging

According to projections from Towards Packaging, the global packaging tape printing market is set to increase from USD 44.71 billion in 2026 to nearly USD 80.21 billion by 2034, reflecting a CAGR of 7.58% during 2025 to 2034.

Ottawa, Sept. 11, 2025 (GLOBE NEWSWIRE) -- The global packaging tape printing market, valued at USD 41.56 billion in 2025, is expected to rise to approximately USD 80.21 billion in 2034, based on a report published by Towards Packaging, a sister firm of Precedence Research.

Get All the Details in Our Solutions - Access Report Sample: https://www.towardspackaging.com/download-sample/5755

The market is gaining traction as businesses increasingly adopt customized and branded packaging solutions to enhance product visibility and security. Rising demand from e-commerce, logistics, and retail sectors is fueling the need for printed tapes that provide both functional sealing and brand promotion. North America dominates the market, supported by its well-established packaging industry, high consumer preference for branded packaging, and strong presence of key players. Technological advancements in printing techniques are further driving innovation and adoption across industries.

What is Meant by Packaging Tape Printing?

Packaging tape printing refers to the process of customizing adhesive tapes with logos, brand names, product information, or decorative designs, transforming them from simple sealing materials into effective branding tools. These tapes serve a dual purpose: they secure packages while also enhancing brand recognition and communication. Commonly used in e-commerce, logistics, manufacturing, and retail, printed packaging tapes act as a cost-effective marketing medium by promoting brand identity during shipping and handling. They also provide tamper-evident features, ensuring product safety. Available in materials like polypropylene, PVC, and paper, printed tapes can be tailored with various colors, patterns, and printing technologies.

What are the Latest Trends in the Packaging Tape Printing Market?

-

Sustainability & Eco-Friendly Materials

Growing demand for recyclable, biodegradable, and plant-based tape materials like paper or compostable substrates, plus greener inks and production processes. This aligns with rising regulatory and consumer pressure to reduce plastic waste and carbon footprints.

-

Smart & Interactive Tape Integration

Printed tapes are increasingly embedding technologies like QR codes, RFID/NFC tags, and even temperature indicators. These features bolster shipment tracking, supply chain transparency, brand engagement, and anti-counterfeiting efforts.

-

Advances in Digital Printing & Customization

Adoption of digital printing techniques enables short-run, cost-effective production with high-resolution, multi-color, and variable-data capabilities. This empowers brands to deliver personalized messaging, seasonal designs, or targeted campaigns with fast turnarounds.

-

Material & Adhesive Innovations

Polypropylene remains the leading substrate due to its durability, tensile strength, and printing clarity, holding around 61% share in 2025. Alongside, hot-melt adhesives are rising, valued for their fast setting and resilience across varying environments. Specialty substrates and high-performance adhesives offering moisture resistance, static control, or extreme temperature tolerance are also gaining traction.

-

E-Commerce & Logistics-Led Demand

Explosive growth in e-commerce has boosted the consumption of printed tapes for tamper-proofing, branding, and shipment integrity. Logistics and e-commerce players now account for a significant share of demand.

-

Personalized Branding & Visual Design Trends

Brands use printed tape as a storytelling and identity tool featuring logos, brand colors, seasonal motifs, multilingual messages, or placeholders for handwritten notes. Design trends include bold color-blocking, high-contrast visuals, or monochrome minimalist styles to support brand visibility and unboxing appeal.

-

Digital Transformation & AI-Powered Production

Manufacturers embrace digital transformation, incorporating AI, IoT, and even blockchain, to optimize production workflows, improve quality control, and enable innovative personalized solutions.

If there is anything you'd like to ask, feel free to get in touch with us @ sales@towardspackaging.com

What Potentiates the Growth of the Packaging Tape Printing Market?

Expansion of Industrial Manufacturing and Retail Operations

The expansion of industrial manufacturing and retail operations significantly bolsters the demand for printed packaging tape. Industrial sectors such as construction, automotive, pharmaceuticals, and FMCG rely on printed tape for enhanced branding, tamper evidence, and safe parcel handling throughout complex supply chains. In retail environments, printed tapes are widely used for branding and logistics support in both in-store stocking and e-commerce fulfilment.

In August 2025, Shurtape introduced its AP 251 Custom-Printed Acrylic Packaging Tape, specifically designed for both manual and automated carton sealing in industrial applications. This tape offers high visual clarity, UV resistance, and durable adhesion, ideal for preserving brand messaging from warehouse to consumer delivery. As factories and retail chains automate packaging lines and prioritize branded, secure shipments, the adoption of custom-printed tapes continues to accelerate across these sectors.

Limitations & Challenges in the Packaging Tape Printing Market

Environmental Concerns & Limited Recycling & Disposal Options

The key players operating in the market are facing issues due to limited recycling & disposal options and environmental concerns. Most printed tapes are made from plastic substrates like polypropylene or PVC, which are not easily recyclable. Growing sustainability regulations and consumer demand for eco-friendly alternatives pose challenges. Recycling facilities often struggle to separate adhesives and inks from tape materials, leading to disposal issues that discourage large-scale adoption in eco-sensitive markets.

More Insights of Towards Packaging:

- Sealing and Strapping Packaging Tapes Market Size & Growth 2034 - The global sealing & strapping packaging tapes market is estimated to reach USD 40.58 billion by 2034.

- Tape Dispenser Market 2025 Expansion Fueled by E-Commerce and Industrial Automation Trends - The global tape dispenser market is forecasted to expand from USD 5.65 billion in 2025 to USD 8.32 billion by 2034, growing at a CAGR of 4.43% from 2025 to 2034.

- Packaging Tapes Market Dynamics: The Role of E-commerce and Logistics in Future Expansion - The packaging tapes market is projected to reach USD 22.39 billion by 2034, expanding from USD 15.42 billion in 2025, at an annual growth rate of 4.24%.

- North America Packaging Tape Printing Market Leadership in 2025 Reinforced by 3M, Shurtape, and UPM New Product Launches - The North America packaging tape printing market is predicted to expand from USD 19.13 billion in 2025 to USD 29.78 billion by 2034.

- Packaging Printing Market Trends, Share, and Growth Analysis 2034 - The packaging printing market is anticipated to grow from USD 404.52 billion in 2025 to USD 611.59 billion by 2034.

- Security Printing Services Market Size Forecast and Competitive Strategies 2034 - The security printing services market is expected to grow from USD 33.16 billion in 2025 to USD 48.43 billion by 2034.

- Tablet Inspection and Printing System Market Investment Opportunities & Competitive Benchmarking - The tablet inspection and printing system market is anticipated to grow from USD 911.33 million in 2025 to USD 1894.39 million by 2034.

- Digital Textile Printing Market Research, Consumer Behavior, Demand and Forecast - The global digital textile printing market was valued at USD 6.77 billion in 2025, is expected to reach approximately USD 19.92 billion by 2034.

- Thermal Printing Market 2025 Outlook: Barcode Printers & Direct Thermal Tech to Dominate USD 79.33 Billion Sector - The thermal printing market is projected to reach USD 79.33 billion by 2034, growing from USD 53.70 billion in 2025, at a CAGR of 4.43%.

- Offset Printing Market 2025 Research Shows High Growth at 14.13% CAGR to 2034 - The global offset printing market is anticipated to grow from USD 3.48 billion in 2025 to USD 11.38 billion by 2034, with a compound annual growth rate (CAGR) of 14.13%.

-

Commercial Printing Market Companies 2025 Growth: Size, Share, Forecast & Key Trends to 2034 - The commercial printing market is forecast to grow from USD 531.51 billion in 2025 to USD 842.39 billion by 2034, driven by a CAGR of 5.25% from 2025 to 2034.

Regional Analysis:

Who is the leader in the Packaging Tape Printing Market?

North America dominates the packaging tape printing market due to its highly developed e-commerce, logistics, and retail industries that generate constant demand for secure and branded packaging solutions. The region benefits from strong industrial manufacturing bases, including pharmaceuticals, food and beverages, and consumer goods, where printed tapes are widely used for branding, product safety, and regulatory compliance. Technological advancements, such as digital and flexographic printing, are readily adopted by North American manufacturers, enabling high-quality, customized solutions.

U.S. Market Trends

The United States dominates the packaging tape printing market due to its well-established e-commerce, logistics, and retail sectors. Rapid growth in online shopping has increased the need for branded, tamper-evident, and secure packaging solutions. Industrial adoption is strong in sectors such as food & beverages, pharmaceuticals, electronics, and consumer goods, where printed tapes provide both protection and brand visibility. Technological advancements, including digital and flexographic printing, allow high-quality, customized designs and fast production. Additionally, sustainability trends encourage the use of recyclable tapes and eco-friendly adhesives. Together, these factors make the U.S. a key driver in the global market.

Canada Market Trends

Canada’s packaging tape printing market is expanding steadily, driven by growth in manufacturing, retail, and e-commerce sectors. Businesses increasingly rely on printed tapes for branding, tamper evidence, and product security across food & beverages, pharmaceuticals, and consumer goods. Advanced printing technologies, such as digital and flexographic solutions, enable short-run, customized production tailored to diverse industry needs. Sustainability remains a major focus, with Canadian companies prioritizing recyclable tapes and eco-friendly adhesives to comply with environmental regulations.

How is the Opportunistic Rise of the Asia Pacific in the Packaging Tape Printing Market?

Asia-Pacific is experiencing the fastest growth in the packaging tape printing market due to rapid industrialization, expanding e-commerce, and increasing retail penetration. Rising manufacturing activities across countries like China, India, and Japan have boosted demand for secure, branded, and tamper-evident packaging solutions. Additionally, the growing adoption of advanced printing technologies, such as digital and flexographic printing, enables high-quality, customized tapes at competitive costs. Government initiatives promoting packaging modernization and the shift toward sustainable materials further support market growth.

Join now to access the latest packaging in industry segmentation insights with our Annual Membership: https://www.towardspackaging.com/get-an-annual-membership

China Market Trends

China’s packaging tape printing market is growing rapidly, fuelled by the expansion of e-commerce and the country’s robust manufacturing sector. Industries such as electronics, automotive, food, and consumer goods increasingly rely on printed tapes for branding, tamper evidence, and secure shipments. Advanced printing technologies, including digital and flexographic solutions, enable high-quality, customizable designs that meet diverse industrial requirements. Sustainability is also becoming a key focus, with rising demand for recyclable and biodegradable tapes. Supportive government policies on packaging standards and environmental regulations further stimulate growth.

India Market Trends

India’s packaging tape printing market is witnessing strong growth, driven by the boom in e-commerce, retail expansion, and rising consumer awareness. Small and medium-sized enterprises increasingly adopt printed tapes for branding, tamper evidence, and product security, making them a cost-effective marketing tool. Adoption of modern printing technologies, such as digital and flexographic printing, allows businesses to produce high-quality, customized designs efficiently. Sustainability trends and government initiatives promoting eco-friendly packaging further support market development. Growth in industrial manufacturing, logistics, and retail sectors also contributes to higher demand, establishing India as a key emerging market in the Asia-Pacific packaging tape printing landscape.

Japan Market Trends

Japan’s packaging tape printing market is growing steadily due to the rise in e-commerce, stringent regulatory standards, and high consumer expectations for secure and aesthetically appealing packaging. Japanese industries, including food, pharmaceuticals, electronics, and consumer goods, rely on printed tapes for branding, product protection, and compliance with packaging regulations. Advanced printing technologies, such as digital and flexographic solutions, facilitate high-resolution, customizable designs, enabling efficient production of short and long runs. Sustainability is a significant focus, with increased adoption of recyclable and eco-friendly materials. Strong technological capabilities and consumer preference for premium packaging drive the continued growth of Japan’s printed tape market.

How Big is the Success of the European Packaging Tape Printing Market?

The European packaging tape printing market is growing at a notable rate due to strong industrial manufacturing, expanding e-commerce, and increasing retail activities across the region. Businesses are adopting printed tapes for branding, tamper-evident sealing, and product protection, particularly in sectors like food & beverages, pharmaceuticals, and consumer goods. Technological advancements, including digital and flexographic printing, enable high-quality, customized designs that meet diverse industry requirements. Additionally, stringent environmental regulations and growing consumer preference for sustainable packaging encourage the use of recyclable and eco-friendly printed tapes. Together, these factors drive steady growth in Europe’s packaging tape printing market.

How Crucial is the Role of Latin America in the Packaging Tape Printing Market?

The Latin America packaging tape printing market is growing at a considerable rate due to the expansion of manufacturing, retail, and e-commerce sectors across countries such as Brazil, Mexico, and Argentina. Increasing demand for branded, tamper-evident, and secure packaging solutions in industries like food & beverages, pharmaceuticals, and consumer goods drives market adoption. Companies are increasingly investing in advanced printing technologies, such as digital and flexographic printing, to produce high-quality, customized tapes. Additionally, growing awareness of sustainability and eco-friendly materials encourages the use of recyclable and biodegradable printed tapes, further supporting market growth across the region.

How does the Middle East and Africa Impact the Packaging Tape Printing Market?

The Middle East and Africa present significant growth opportunities in the packaging tape printing market due to rapid industrial development, expanding e-commerce, and rising retail activities. Countries like the UAE, Saudi Arabia, Egypt, and South Africa are driving demand for branded, tamper-evident, and secure packaging solutions across sectors such as automotive, electronics, food & beverages, and consumer goods. Adoption of advanced printing technologies, including digital and flexographic printing, allows high-quality, customized tape production to meet diverse industrial needs. Additionally, growing focus on sustainability and eco-friendly materials encourages the use of recyclable and biodegradable printed tapes, further supporting market expansion.

Elevate your packaging strategy with Towards Packaging. Enhance efficiency and achieve superior results - schedule a call today: https://www.towardspackaging.com/schedule-meeting

Segment Outlook

Tape Type Insights

The polypropylene (BOPP) tapes segment dominates the packaging tape printing market due to their excellent strength, durability, and clarity, making them ideal for securing packages during transit. Their superior adhesion, resistance to moisture, and ability to withstand varying temperatures enhance their reliability across diverse industrial and retail applications. Additionally, BOPP tapes offer high print quality, enabling clear branding and messaging. Cost-effectiveness, ease of use, and compatibility with digital and flexographic printing technologies further reinforce their widespread adoption, solidifying their position as the preferred choice in the market.

The kraft paper tape segment is the fastest-growing in the market due to increasing demand for sustainable and eco-friendly packaging solutions. Made from renewable, recyclable, and biodegradable materials, kraft paper tapes appeal to environmentally conscious businesses and consumers. They offer strong adhesion, durability, and compatibility with water-based inks for high-quality printing. Rising adoption in e-commerce, retail, and industrial sectors, coupled with regulatory support for sustainable packaging, further accelerates growth, positioning kraft paper tape as a preferred alternative to traditional plastic-based tapes.

Printing Technology Insights

The flexographic printing segment dominates the packaging tape printing market due to its efficiency, versatility, and cost-effectiveness for large-scale production. It enables high-speed printing with consistent quality on various substrates, including polypropylene, PVC, and kraft paper tapes. Flexography supports multi-color designs, clear logos, and branding while maintaining the durability and adhesion of the tape. Its ability to handle long runs economically, combined with compatibility with diverse adhesives and substrates, makes it the preferred choice for manufacturers seeking reliable, high-quality, and visually appealing printed packaging tapes across industries.

The digital printing segment is the fastest-growing in the market due to its ability to provide high-quality, customizable, and short-run printing solutions. It enables variable data printing, multi-color designs, and intricate graphics without the need for expensive plates or setup, making it ideal for personalized branding and seasonal campaigns. Its flexibility, quick turnaround, and compatibility with various tape substrates support small and medium enterprises as well as large corporations. Rising demand for unique, visually appealing, and branded packaging drives the rapid adoption of digital printing.

Application Insights

The branding and advertising segment dominates the packaging tape printing market because companies increasingly use printed tapes as a cost-effective marketing tool to enhance brand visibility and recognition. Printed tapes allow businesses to display logos, slogans, and brand colors directly on packages, creating a strong visual impact during shipping, handling, and unboxing. This segment is widely adopted across e-commerce, retail, and industrial sectors, where brand differentiation and consumer engagement are critical. The effectiveness, low cost, and dual functionality of protection and promotion reinforce its dominance.

The security and tamper-evident segment is the fastest-growing in the market due to increasing concerns over product safety, counterfeiting, and unauthorized access during transit. Printed tapes in this segment provide clear visual indicators if a package has been opened or tampered with, ensuring integrity and consumer trust. Rising adoption in e-commerce, pharmaceuticals, electronics, and high-value goods sectors drives demand. Additionally, advancements in printing technologies allow for customized security features, such as unique codes, holograms, or patterns, further accelerating growth in this critical market segment.

End-User Industry Insights

The e-commerce and logistics segment dominates the packaging tape printing market due to the exponential growth of online retail and global shipping activities. Printed tapes provide both secure sealing and branding, making them essential for protecting packages while enhancing brand visibility during transit. This segment benefits from high-volume usage across warehouses, fulfillment centers, and distribution networks. The adoption of advanced printing technologies ensures clear, durable logos and messaging on tapes, while the need for tamper-evident solutions further reinforces the segment’s prominence in e-commerce and logistics operations.

The electronics and industrial goods segment is the fastest-growing in the market due to increasing demand for secure, tamper-evident, and branded packaging in high-value shipments. Printed tapes help protect sensitive equipment, components, and machinery during transit while providing clear identification, compliance labeling, and branding. Rapid industrialization, expanding manufacturing activities, and the growth of exports from electronics hubs drive adoption. Advanced printing technologies enable durable, high-quality designs on tapes compatible with various substrates, further accelerating growth in this critical segment of industrial and electronics packaging.

Adhesive Type Insights

The hot-melt adhesive tape segment dominates the packaging tape printing market due to its strong adhesion, quick setting time, and excellent performance across diverse surfaces and environmental conditions. These tapes are highly reliable for securing packages in e-commerce, logistics, and industrial applications, ensuring durability during transit and storage. Their compatibility with various substrates, including polypropylene and kraft paper, combined with ease of application on manual or automated sealing lines, makes them highly preferred. The ability to support high-quality printed designs further strengthens their dominance in the market.

The acrylic adhesive tape segment is the fastest-growing in the market due to its superior resistance to temperature variations, UV exposure, and aging, making it ideal for long-term storage and outdoor applications. Its strong adhesion on diverse surfaces, including corrugated cartons and plastics, ensures secure sealing during transit. Additionally, acrylic tapes support high-quality printing for branding and tamper-evident purposes. Growing demand from e-commerce, logistics, and industrial sectors, coupled with increasing emphasis on durable and reliable packaging solutions, drives rapid adoption of acrylic adhesive tapes.

Access our exclusive, data-rich dashboard dedicated to the Packaging Tape Printing Market- built specifically for decision-makers, strategists, and industry leaders. The dashboard features comprehensive statistical data, segment-wise market breakdowns, regional performance shares, detailed company profiles, annual updates, and much more. From market sizing to competitive intelligence, this powerful tool is one-stop solution to your gateway.

Access Now: https://www.towardspackaging.com/contact-us

Recent Breakthroughs in the Global Market:

- In April 2025, TamperTech collaborated with DataLase to integrate DataLase’s photonic printing technology into tamper tape with the goal of combining tracking, authentication, and security into a single solution.

- In November 2024, Tesa, a world leader in adhesive tape solutions, demonstrated its cutting-edge flexographic tape solutions designed specifically for the narrow-web sector at Labelexpo India 2024. The stand functional as a stage to showcase items made for gripping, splicing, and plate mounting applications, as well as to promote partnerships with clients and business associates.

Global Packaging Tape Printing Market Players

- 3M Company

- Avery Dennison Corporation

- Intertape Polymer Group Inc.

- Tesa SE (Beiersdorf AG)

- Scapa Group Ltd.

- Shurtape Technologies, LLC

- Nitto Denko Corporation

- Berry Global Inc.

- Advance Tapes International Ltd.

- Pro Tapes & Specialties, Inc.

- Cintas Packaging

- Western Paper Industries (India)

- Can-Do National Tape

- American Packaging Corporation

- Rajapack Ltd. (Raja Group)

- Packlane

- Sticker Mule (custom printed tapes)

- Phoenix Tape & Supply

- Seal King Ind Co., Ltd.

- Shanghai Yongguan Adhesive Products Corp.

Global Packaging Tape Printing Market Segments

By Tape Type

- Polypropylene (BOPP) Tapes

- Printed carton sealing tapes

- Suitable for high-speed applications

- PVC Tapes

- Premium grade, quieter unwind

- Kraft Paper Tapes

- Eco-friendly alternative

- Filament & Reinforced Tapes

- Heavy-duty printing for industrial use

- Masking & Specialty Tapes

By Printing Technology

- Flexographic Printing

- High-speed, cost-effective for large runs

- Digital Printing

- Variable data printing, lower setup cost

- Inkjet Printing

- Screen Printing

- Offset Printing (limited use)

By Application

- Branding & Advertising

- Custom logos, color-coded tapes

- Security & Tamper Evidence

- "VOID" messages, security seals

- Product Identification & Traceability

- Handling Instructions (e.g., fragile, this side up)

- Decorative or Thematic Packaging (e.g., holidays, events)

By End User Industry

- E-commerce & Logistics

- Amazon, Flipkart, DHL, and FedEx use branded tape

- Retail & FMCG

- Food & Beverage

- Pharmaceuticals

- Electronics & Industrial Goods

- Apparel & Lifestyle

- Automotive & Spare Parts

By Adhesive Type

- Hot Melt Adhesive Tapes

- Acrylic Adhesive Tapes

- Rubber-Based Adhesive Tapes

- Solvent-Based Adhesives

By Region

- North America

- U.S.

- Canada

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Brazil

- Mexico

- Argentina

- Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait

Invest in Our Premium Strategic Solution: https://www.towardspackaging.com/price/5755

Become a Valued Research Partner with Us - Schedule a meeting: https://www.towardspackaging.com/schedule-meeting

Request a Custom Case Study Built Around Your Goals: sales@towardspackaging.com

About Us

Towards Packaging is a global consulting and market intelligence firm specializing in strategic research across key packaging segments including sustainable, flexible, smart, biodegradable, and recycled packaging. We empower businesses with actionable insights, trend analysis, and data-driven strategies. Our experienced consultants use advanced research methodologies to help companies of all sizes navigate market shifts, identify growth opportunities, and stay competitive in the global packaging industry.

Stay Connected with Towards Packaging:

- Find us on Social Platforms: LinkedIn | Twitter | Instagram

- Subscribe to Our Newsletter: Towards Sustainable Packaging

- Visit Towards Packaging for In-depth Market Insights: Towards Packaging

- Read Our Printed Chronicle: Packaging Web Wire

-

Get ahead of the trends – follow us for exclusive insights and industry updates:

Pinterest | Medium | Tumblr | Hashnode | Bloglovin | LinkedIn – Packaging Web Wire - Contact: APAC: +91 9356 9282 04 | Europe: +44 778 256 0738 | North America: +1 8044 4193 44

Towards Packaging, Your Trusted Research and Consulting Partner, Has Been Featured Across Influential Industry Portals - Explore the Coverage:

- Is it finally safe to ditch your phone case? I put it to the test

- Battery Brands Charge Forward with Plastic-Free Packaging

- Why Non-corrugated Boxes Are the Future of Packaging

- Ampoules Packaging Market Size Expected to Reach $11.27 Bn by 2034

- Flexible plastic pouches projected to boom over the next decade

- GLOBAL PET FOOD PACKAGING MARKET SET TO DOUBLE BY 2032

- The Skinny on the Skin Packaging Market

- Healthcare Goes Green & Sterile

- The Different Types of Adhesives for Paper Packaging

- Child-Resistant Packaging: Cannabis and So Much More

Towards Packaging Releases Its Latest Insight - Check It Out:

- Plastic Aerosol Packaging Market - Intelligence, Benchmarking, Consumer Insights & Growth Strategies

- Post-Consumer Recycled (PCR) Pouch Market - Disruptive Trends and Future Potential

- Cross-linked Polyethylene Market - Driven by 6.95% CAGR

- Sterile Medical Packaging Market - Size Driven by 11.05% CAGR

- Zero Waste Packaging Market - Driven by 9.65% CAGR

- Tube Packaging Market - Driven by 5.82% CAGR (2025-34)

- Rigid Bulk Packaging Market - Drives at 4.63% CAGR

- Plastic Compounding Market - Driven by 7.43% CAGR

-

Rigid Packaging Market - Driven by 4.8% CAGR (2025-34)

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.